The

Raspberry Pi, just sitting there, asking to be played with...

As I

looked over my existing projects I noticed this sad little lone R-Pi

sitting on my desk. Some time ago I bought it. Played with it a bit,

installed NOOB image on the SD card, connected I2C LCD text display

to it and a shutdown switch and played a bit with GPIO programming in

Python. I want to make a car trip computer out of this R-Pi. You

know, a computer that will read car's ECU via OBD2 port and display

information in real time, like the average and current gas usage,

trip time and length, how many miles left on the remaining fuel and

such. In the future perhaps I could add a camera and trip log. This

may be a cool project. I commute to work 15 miles, so there will be

plenty opportunity to test the toy.

I

remembered that this LCD screen, connected to GPIO pins via some

prototyping wire (female connectors at both ends) gave me a lot of

trouble related to poor contact, so I decided to upgrade it and make

a dedicated connector with wires soldered to it. I also need a keypad

for the project, but since I did not buy or make one yet, I just

connected a LCD and a shutdown switch at this time.

The

LCD takes just 4 wires – 5V, GND, SDA and SCL

(I2C and power, Pi's GPIO pins #2, 6, 3, 5 respectively). The

unfortunate thing is that the R-Pi's logic is 3.3V, however this

display's power voltage requirement and logic is 5V. I tried to power

it from Pi's 3.3V pin hoping that it has some built in tolerance,

however the display would not work then. Therefore I powered the

screen from Pi's 5V pin with a bit of scare that I might damage the

Pi's GPIO port, however this seems to work fine. It looks like the

device accepts 3.3V logic, just needs to be powered by 5V to operate.

I guess it should be OK as long as I am not sending the input to R-Pi

in the 5V level. Since LCD is an output device, this is not the case.

The temporary connection I made previously suffered from poor contact

and I often had voltage drops that caused information loss on the

display, even with the 5V power connected to the device. With the new

connector things look much better and the display is finally

reliable.

Connections

diagram.

The

code.

I

found very useful information here.

It presents the driver in Python for LCD display that is in turn driven by

PCF8574 expander chip, which is basically an I2C hardware driver for

the LCD display.

It is

easy to implement and start programming your LCD screen in Python

right away (assuming you already installed and configured your GPIO

libraries).

The

actual driver code listed below, lcddriver.py was taken from above web site at the time I made the project:

import smbus

from time import *

# General i2c device

class so that other devices can be added easily

class i2c_device:

def __init__(self,

addr, port):

self.addr = addr

self.bus =

smbus.SMBus(port)

def write(self,

byte):

self.bus.write_byte(self.addr,

byte)

def read(self):

return

self.bus.read_byte(self.addr)

def

read_nbytes_data(self, data, n): # For sequential reads > 1 byte

return

self.bus.read_i2c_block_data(self.addr, data, n)

class lcd:

#initializes

objects and lcd

'''

Reverse Codes:

0: lower 4 bits of

expander are commands bits

1: top 4 bits of

expander are commands bits AND P0-4 P1-5 P2-6

2: top 4 bits of

expander are commands bits AND P0-6 P1-5 P2-4

'''

def __init__(self,

addr, port, reverse=0):

self.reverse =

reverse

self.lcd_device =

i2c_device(addr, port)

if self.reverse:

self.lcd_device.write(0x30)

self.lcd_strobe()

sleep(0.0005)

self.lcd_strobe()

sleep(0.0005)

self.lcd_strobe()

sleep(0.0005)

self.lcd_device.write(0x20)

self.lcd_strobe()

sleep(0.0005)

else:

self.lcd_device.write(0x03)

self.lcd_strobe()

sleep(0.0005)

self.lcd_strobe()

sleep(0.0005)

self.lcd_strobe()

sleep(0.0005)

self.lcd_device.write(0x02)

self.lcd_strobe()

sleep(0.0005)

self.lcd_write(0x28)

self.lcd_write(0x08)

self.lcd_write(0x01)

self.lcd_write(0x06)

self.lcd_write(0x0C)

self.lcd_write(0x0F)

# clocks EN to

latch command

def

lcd_strobe(self):

if self.reverse ==

1:

self.lcd_device.write((self.lcd_device.read()

| 0x04))

self.lcd_device.write((self.lcd_device.read()

& 0xFB))

if self.reverse ==

2:

self.lcd_device.write((self.lcd_device.read()

| 0x01))

self.lcd_device.write((self.lcd_device.read()

& 0xFE))

else:

self.lcd_device.write((self.lcd_device.read()

| 0x10))

self.lcd_device.write((self.lcd_device.read()

& 0xEF))

# write a command

to lcd

def lcd_write(self,

cmd):

if self.reverse:

self.lcd_device.write((cmd

>> 4)<<4)

self.lcd_strobe()

self.lcd_device.write((cmd

& 0x0F)<<4)

self.lcd_strobe()

self.lcd_device.write(0x0)

else:

self.lcd_device.write((cmd

>> 4))

self.lcd_strobe()

self.lcd_device.write((cmd

& 0x0F))

self.lcd_strobe()

self.lcd_device.write(0x0)

# write a character

to lcd (or character rom)

def

lcd_write_char(self, charvalue):

if self.reverse ==

1:

self.lcd_device.write((0x01

| (charvalue >> 4)<<4))

self.lcd_strobe()

self.lcd_device.write((0x01

| (charvalue & 0x0F)<<4))

self.lcd_strobe()

self.lcd_device.write(0x0)

if self.reverse ==

2:

self.lcd_device.write((0x04

| (charvalue >> 4)<<4))

self.lcd_strobe()

self.lcd_device.write((0x04

| (charvalue & 0x0F)<<4))

self.lcd_strobe()

self.lcd_device.write(0x0)

else:

self.lcd_device.write((0x40

| (charvalue >> 4)))

self.lcd_strobe()

self.lcd_device.write((0x40

| (charvalue & 0x0F)))

self.lcd_strobe()

self.lcd_device.write(0x0)

# put char function

def lcd_putc(self,

char):

self.lcd_write_char(ord(char))

# put string

function

def lcd_puts(self,

string, line):

if line == 1:

self.lcd_write(0x80)

if line == 2:

self.lcd_write(0xC0)

if line == 3:

self.lcd_write(0x94)

if line == 4:

self.lcd_write(0xD4)

for char in

string:

self.lcd_putc(char)

# clear lcd and set

to home

def

lcd_clear(self):

self.lcd_write(0x1)

self.lcd_write(0x2)

# add custom

characters (0 - 7)

def

lcd_load_custon_chars(self, fontdata):

self.lcd_device.bus.write(0x40);

for char in

fontdata:

for line in char:

self.lcd_write_char(line)

Example

of use, the script that displays welcome banner, hello.py:

import

lcddriver

from

time import *

lcd

= lcddriver.lcd()

lcd.lcd_clear()

lcd.lcd_display_string("*------------------*",1);

lcd.lcd_display_string("|System

is running.|",2)

lcd.lcd_display_string("*------------------*",3);

I

modified few start-up and shutdown handling scripts to run the

scripts that display information on the LCD screen. This way I have

neat messages that you can see on the pictures when the system is

booted up and ready to use and also when I press the shutdown button,

I get the information displayed about the shutdown progress. Since

there is only one display and there are multiple scripts or programs

that would like to write data to it, the proper way to do it would be

to create some sort of a server that would take the requests from

clients and relay them to the LCD screen. For now however I write

them directly to the LCD screen since this was meant as a demo and

proof of operation.

E.g:

the script displaying welcome banner, hello.py, was added in

script /etc/rc.local at the end:

cd

~pi/src/py/i2c/lcd/hello

python

hello.py &

cd

-

The

script that polls GPIO pin #18 for low state, then shuts down the

R-Pi and displays adequate messages to LCD screen, safeoff.py:

import

lcddriver

from

time import *

import

RPi.GPIO as GPIO

import

os

import

time

GPIO.setmode(GPIO.BCM)

GPIO.setup(18,

GPIO.IN,pull_up_down=GPIO.PUD_UP)

lcd

= lcddriver.lcd()

while

True:

if(GPIO.input(18) ==

0):

lcd.lcd_clear()

lcd.lcd_display_string("Shutting

down...",1)

os.system("sudo

shutdown -h now")

break

time.sleep(2)

progress

= "/"

while

True:

lcd.lcd_display_string(progress,2)

progress=progress+"/"

time.sleep(1);

was

added to /etc/rc.local script as well:

cd

~pi/src/py/i2c/lcd/safeoff

python

safeoff.py &

cd

-

The

script that displays the final message, systemoffmsg.py:

import

lcddriver

lcd

= lcddriver.lcd()

lcd.lcd_clear()

lcd.lcd_display_string("System

is halted.",1)

And

the script that displays the system restart message, sysrestmsg.py:

import

lcddriver

lcd

= lcddriver.lcd()

lcd.lcd_clear()

lcd.lcd_display_string("System

will restart.",1)

lcd.lcd_display_string("Wait

for welcome",2)

lcd.lcd_display_string("screen...",3)

were

added to /etc/init.d/halt and /etc/init.d/reboot

respectively:

log_action_msg

"Will now halt"

python

~pi/src/py/i2c/lcd/safeoff/sysoffmsg.py >/dev/null 2>&1

halt -d -f

$netdown $poweroff $hddown

}

and

do_stop

() {

# Message

should end with a newline since kFreeBSD may

# print more

stuff (see #323749)

log_action_msg

"Will now restart"

python

~pi/src/py/i2c/lcd/safeoff/sysrestmsg.py

reboot -d -f

-i

}

Pictures.

|

Image

1: R-Pi with I2C LCD and shutdown switch connected before it was put

in the case.

|

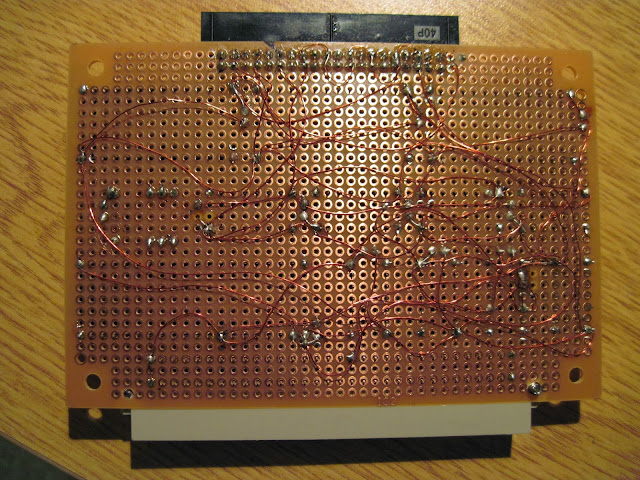

|

Image

2: Detailed view of GPIO connector.

|

|

Image

3: Detailed view of I2C LCD connector.

|

|

Image

4: R-Pi in case with LCD attached on top with the rubber bands.

|

|

Image

5: R-Pi, side view.

|

|

Image

6: R-Pi, back side view, a bit of creativity with a Lego (C) block

supporting the LCD screen.

|

|

Image

7: ...and the SD card side view.

|

|

Image

8: Welcome banner displayed on LCD after R-Pi boot-up.

|

|

Image

9: Testing shutdown button.

|

|

Image

10: Shutdown progress displayed.

|

|

Image

11: It is now safe to power off your R-Pi.

|

Well, this is it. Nothing much, but perhaps this article will help somebody doing first steps in R-Pi exploration or looking for the information related to the topic of connecting LCD or making a safe power-off switch for R-Pi's embedded use (with no keyboard and HDMI display).

Thanks for reading.

Marek Karcz, 11/16/2013